Introduction

GFB’s range of Lightweight Under-Drive Pulley Kits are designed to improve acceleration by reduce the rotational mass (inertia) on the crankshaft as well as parasitic loads from the driven accessories.

The pulleys are manufactured from 6061 T6 billet aluminium on the latest precision CNC machines, and typically save up to 2.5kg of weight over the factory pulleys. Under-driving is achieved through the use of a smaller diameter crank pulley, which reduces the amount of drag from the accessories, particularly at high RPM. Note that GFB take care to ensure that accessory performance is not affected.

Performance Testing

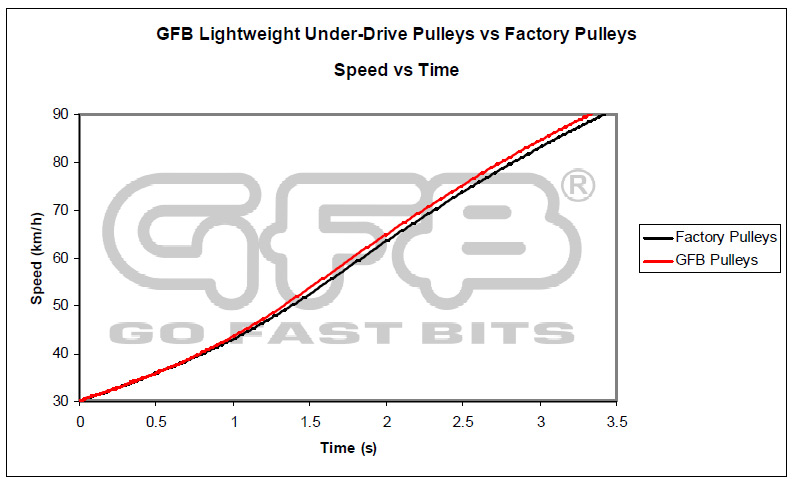

To determine the effectiveness of the GFB Lightweight Under-Drive Pulleys, a series simple real-world tests were performed using a G-Tech Pro Competition to record vehicle performance before and after fitting a GFB Lightweight Under-Drive Pulley kit.

A G-Tech meter is a device that records G-Force, time, and engine RPM 100 times per second. From these measurements, it is able to calculate road speed, distance travelled, and engine power/torque with very good repeatability. So why didn’t we dyno test the car?

Easy – all we (and the user) really want to know is “does my car go faster as a result of this modification”?

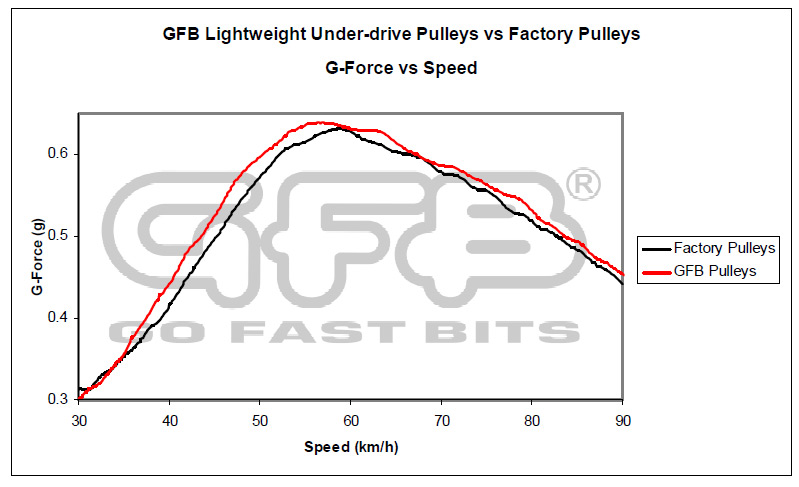

The G-Tech is perfectly suited for this, since it measures actual G-Force and time, which is exactly what we’re really interested in – G-Force is a direct measurement of how fast a car is accelerating, which is the thrust you feel by the seat of your pants when you mash the throttle – you can’t get more real-world than that!

In addition to the above, there is another very important reason why dyno testing is not used in this case:

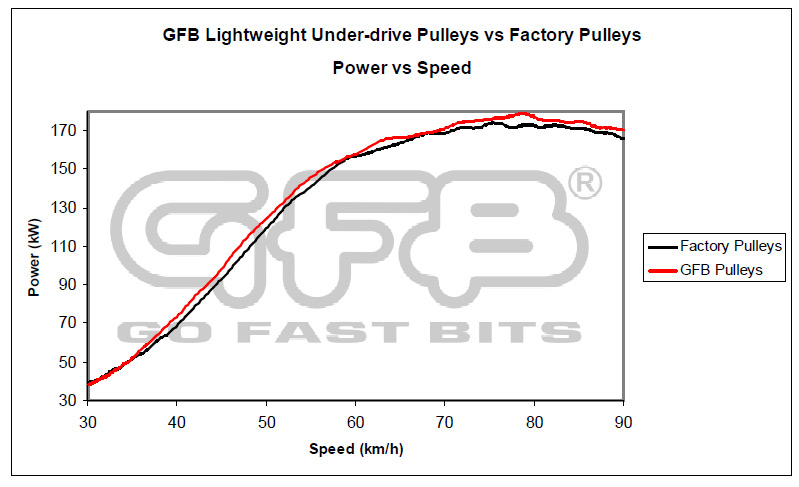

The GFB lightweight under-drive pulleys do not increase the amount of torque or power developed by the engine. They simply reduce the amount of mass that the engine must accelerate. Therefore, the faster the engine RPM is increasing, the greater the benefit will be from reduced pulley mass.

This effect does actually show up as a power increase on a dyno, however dyno testing does not replicate actual on-road acceleration, since the engine acceleration (as opposed to the car’s acceleration) is regulated to a constant and relatively slow rate of increase. When driving the car on the road, acceleration will vary in response to the engine torque curve (as well as other variables that need to be minimised, as discussed below). Therefore the power improvement shown on a dyno will be different (usually less) from what is calculated by the G-Tech based on the car’s actual acceleration.

Test procedures

The tests were performed on an MY07 Subaru STi, with the only other modifications being a GFB Respons TMS diverter valve, a 3” turbo-back exhaust and an ECU tune. With the factory pulleys in place, a series of in-gear pulls were recorded using the GTech meter. Three runs each were performed in 1st, 2nd and 3rd gear. The clutch was engaged from a standstill smoothly and gently up to a slow speed, whereupon the accelerator was floored and the engine swept right through its full RPM range (except for 3rd gear, where the tests had to be cut short due to the road speed limit), just as it would be on a dyno. No gear shifts or drag-racing type launches were included in the testing to eliminate as many variables as possible.

The GFB pulleys were then fitted, and the tests repeated.

Note that in the interest of minimising any potential sources of error, the following points are observed:

- The same stretch of straight, level road was used for each run

- The driving conditions between each pass were replicated so the engine and

- intercooler received the same amount of cooling between passes

- All tests were performed on the same day all within an hour – the ambient

- temperature was the same (25 degrees C) from start to finish

- The wind on the day was less than 8km/h during the testing

- The total distance driven during the complete test series was less than 13km (including to and from the location where the pulley swap was performed), so

- the fuel load variation would have been less than 2 litres.