Introduction

Compressor surge was explored in depth in our discussion paper “The Truth About Compressor Surge”, and it is worth taking the time to read this article as background. However, in that article the phenomenon of compressor surge occurring during acceleration with an open throttle was only briefly mentioned as at the time it was not particularly common. With modern engines and turbos now capable of making high boost at low RPM, open throttle compressor surge is becoming more common and is worthy of its own article.

What is open throttle compressor surge?

Compressor surge is a condition where the airflow through the turbo’s compressor becomes “unstable” and is usually evident as oscillating boost and a “fluttering” or “chopping” sound. This occurs when the car’s ECU has been tuned to generate high boost pressure at low RPM, and the driver will generally notice the surge happening in higher gears when accelerating at part or full throttle on a highway. Minor surge is usually just a soft fluttering sound, but more severe surge can cause the car to physically jerk, and the boost gauge will oscillate rapidly. Typically, the surge abates as RPM increases.

Often, open-throttle compressor surge is incorrectly diagnosed as the diverter or blow-off valve rapidly opening and closing, which is simply not true.

What causes open throttle compressor surge?

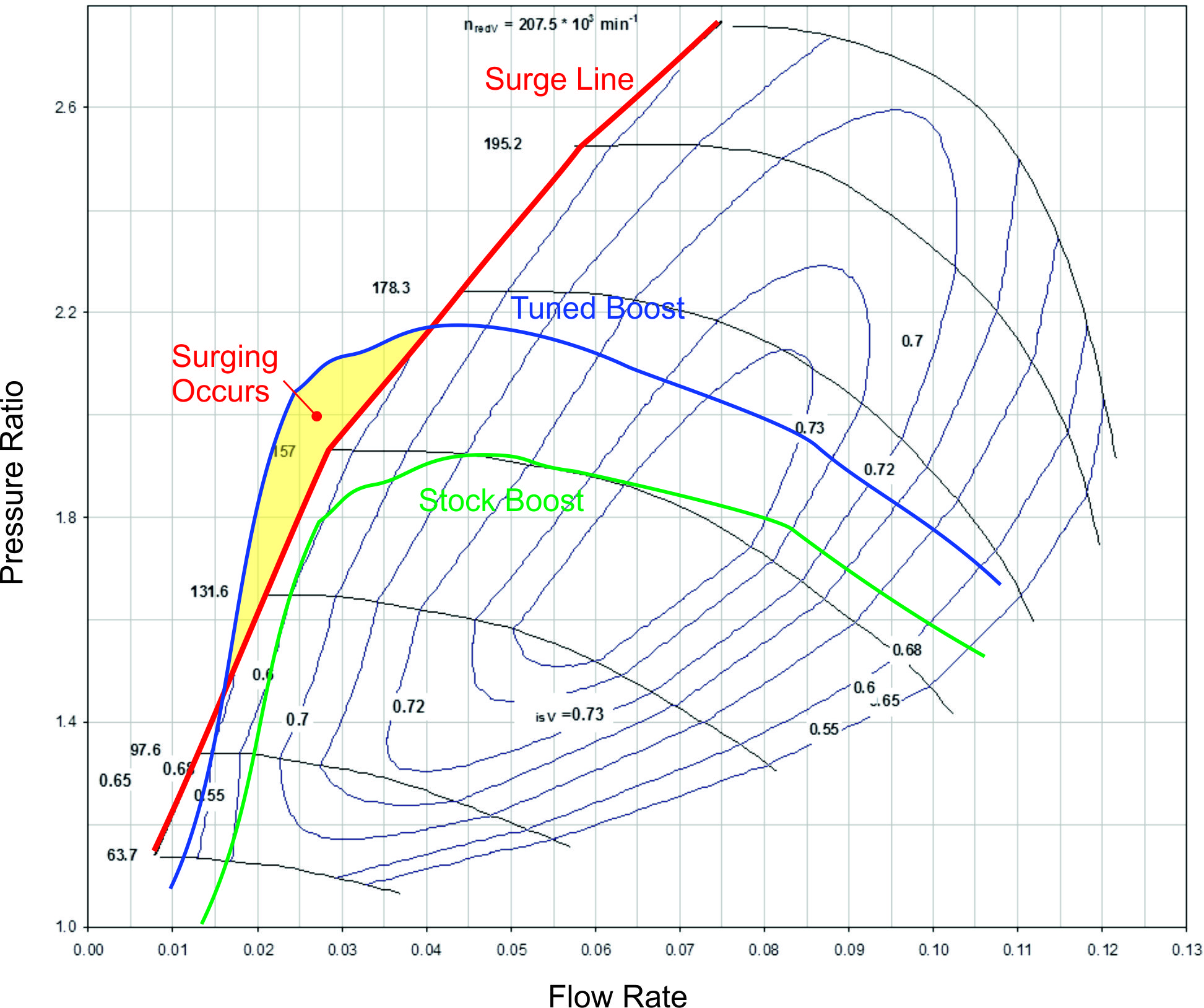

As discussed in “The Truth About Compressor Surge”, the environment in which the turbo is said to be operating in surge involves a high pressure ratio and a low flow rate. These conditions can be met by rapidly closing the throttle for gearshift (as the flow rate suddenly drops and the pressure ratio increases), but in this paper we’re interested in the case where the throttle remains open (or partially open) and the boost pressure is high, but the RPM and therefore the airflow is low enough to cause the turbo to operate in the surge region (the yellow area on the compressor map below)