Turbocharger Efficiency

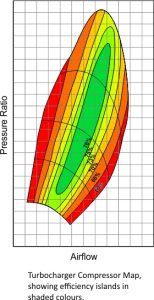

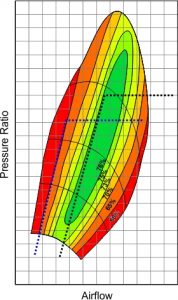

When the time comes to choose a new turbo, or the conversation at the pub turns to turbos, no doubt the term “turbocharger efficiency” will come up. Take a look at any turbo compressor map and you’ll see what are referred to as “efficiency islands/lines/contours”, which tell you how “efficient” the turbo is at certain flow and pressure conditions.

a look at any turbo compressor map and you’ll see what are referred to as “efficiency islands/lines/contours”, which tell you how “efficient” the turbo is at certain flow and pressure conditions.

But, what does this “efficiency” actually refer to? How much fuel it uses? How well it converts exhaust energy into boost? How much of your tyres it leaves on the road for a given throttle opening?

None of these actually (or unfortunately, depending on how you look at it!).

The efficiency of a turbocharger as indicated by a compressor map, refers to the adiabatic efficiency of the compressor. That is, how little extra heat is put into the charge by the turbo during compression of the air.

Now, I say extra heat because the act of compressing a gas always increases its temperature – that is a completely unavoidable consequence of making sweet, sweet boost! The temperature increase of air when compressed under “ideal” conditions is defined by the ideal gas law, and represents a compression process that is 100% efficient. This is what the compressor’s efficiency is compared against.

Let’s look at an example. If atmospheric pressure is 1 bar, and our boost pressure is also 1 bar (meaning 2 bar absolute), we have a pressure ratio of 2 – i.e. we are effectively doubling the atmospheric pressure. Starting at a temperature of 20 degC, if we could compress the air 100% efficiently (i.e. adiabatic compression), the temperature during this process would rise to 84 degC.

But a turbo compressor is less than 100% efficient, meaning it adds more heat than what we’ve calculated above for an ideal process.

Going back to our example above and using the same conditions, if our compressor efficiency is 75% it means the actual outlet temperature is now just over 105 degC.

But what if the turbo were being operated at a point on the compressor map where the efficiency is only 65%? Our outlet temp for the same conditions rises to 119 degC.

So why do we care how adiabatically efficient the turbo compressor is? Well, an intercooler cannot realistically extract all of the extra heat added by an inefficient turbo, which means the air going into the engine is hotter and therefore less dense for a given boost pressure – just because you doubled the pressure doesn’t mean you get double the oxygen to burn. The hotter the charge air is, the less oxygen you get for the same boost pressure. You also run a higher risk of detonation, so the ignition timing needs to be retarded, and everything in the engine is more thermally stressed.

So you’ve gone to all this trouble of making boost, but if the turbo is operating at low adiabatic efficiency, you’re not getting the same amount of power as you would if the turbo operates at higher efficiencies.

On the compressor map opposite, you can see two examples of airflow plots from different engines. The blue dashed line shows an engine that is a suitable match for the this turbo, whilst the black dashed line is representative of a larger engine whose airflow is too high for this turbo – at high RPM the airflow requirement to maintain the desired pressure ratio means the compressor is operating well outside of its efficiency range, which is effectively choking the engine and super-heating the charge air. In this case, a larger turbo should be considered.

That’s why a compressor map is an important tool that can be used to select the best turbo for your car, and to ensure it will be operating at the highest efficiency possible during the engine conditions where you plan to do most of your driving.