Engines with turbochargers invariably suffer from poorer throttle response than their normally aspirated counterparts, because of the time it takes for the turbo to build boost pressure when the throttle is opened. This is known as turbo lag, and this paper looks at the role a diverter valve plays in managing boost and turbo lag.

Introduction to Turbo Lag

Turbo lag:

A measure of the delay between when a turbocharged engine’s throttle is opened, and a “significant portion” of the maximum boost pressure is available.

Boost threshold:

Turbo lag should not be confused with boost threshold, which for simplicity’s sake we’ll say is the engine RPM above which the turbo is capable of producing a “significant portion” of its maximum boost pressure.

For example, stamping the throttle open at 1500RPM and having to wait until 3000RPM for boost is not so much lag as it is a function of the engine and turbo system’s boost threshold. Once the engine is operating above the boost threshold however, then the delay when the throttle is opened can be assumed to be turbo lag.

Diverter Valve, or “DV”

a.k.a. BOV, bypass, dump, recirculation & blow-off valve:

A valve fitted to the intercooler piping between the turbo’s compressor and the engine’s throttle body. A signal hose typically connects the top of the valve to the intake manifold after the throttle. In its simplest form, when the throttle is closed and boost is present in the intercooler, the Blow Off Valve opens up (as a result of the signal hose switching from boost pressure to vacuum) and provides a relief path for air to escape.

The air can be vented straight out to atmosphere, or it can be recirculated back to the turbo’s intake. Generally, the term blow-off or dump valve is used to describe a valve that vents to atmosphere, whilst recirculating (or recirc), bypass or diverter valve is applied when the air is vented back to the turbo’s intake. In this article we are not concerned with what is done with the vented air.

TMS (Turbo Management Solution) valve:

A term used by GFB to describe a valve designed to enhance or supplement the basic factory DV functionality through the ability to adjust aspects of the valve’s operation critical to its performance. It may be either atmosphere or recirc venting, being differentiated from a typical DV by the fact that its operation is designed to maximise throttle response and boost for improved performance outcomes.

Spool-up:

Typically defined as the process of speeding up the turbo until full boost is achieved.

Compressor Surge:

The nature and causes of compressor surge could cover an entire topic on their own, but for the purposes of this discussion, compressor surge is a condition that can occur when the throttle is closed on a turbo car where no DV is present. The pressurised air in the intercooler and pipes has nowhere to go and exits back out through the turbo’s compressor.

This causes a characteristic fluttering sound (that is often incorrectly mistaken for a certain type of aftermarket BOV or “wastegate chatter”), and also results in pressure spikes and pulses in the intercooler piping.

Compressor surge varies in severity – at low RPM/boost it is generally nothing to be concerned about, but in highly stressed turbos it has the potential to accelerate wear or even cause damage to the compressor. Additionally, the turbo will slow rapidly as air escapes back out through the compressor.

It is a task of a DV to provide a relief path for air to escape in order to prevent compressor surge.

Evolution of the Blow Off Valve

When turbos were in their infancy in motorsport, race engineers were always looking for ways to reduce lag, and the DV was one of the methods that was developed and is still in use today. By eliminating compressor surge, the turbo would not slow as rapidly when the throttle was lifted. Since turbos in that era were slow to spool up, maintaining shaft speed was a high priority.

During the early ‘90s, it became common practice for car manufacturers to fit DVs to their turbocharged models to prevent compressor surge. Here’s where the purpose of the DV changed however, and why there are still improvements to be found.

As far as car manufacturers are concerned, the process of preventing compressor surge has the benefit of eliminating the associated fluttering noise – strange noises, no matter how cool they may sound to an enthusiast, are generally to be avoided in production vehicles.

To achieve this task, factory fitted DVs tend to work on a common principle, which is to open the valve readily and fully, usually as soon as the manifold pressure drops into vacuum, effectively relieving the maximum amount of air regardless of whether it is necessary or not. This design is like a blanket solution to ensure compressor surge is completely eliminated. GFB Discussion Paper

Using this principle, it is common for a factory DV to be wide open at all times except when the engine is on boost. This effectively prevents the turbo from building any amount of boost pressure until the valve closes, to the detriment of throttle response.

Fitting a larger intercooler can actually make the problem worse since the turbo has a much larger volume to fill when the throttle is opened.

Because factory DV have worked this way for so long, it is commonly believed that the principle behind them is to allow the turbo to “freewheel” whilst the throttle is shut, thus resulting in higher turbo RPM when the throttle is re-opened. Using this argument, it is also assumed that venting as much air as quickly as possible must surely aid the turbo in “freewheeling”, and therefore any aftermarket DV that replaces the factory one should flow more to be considered an improvement.

Whilst the above may seem a sound argument, there is a flaw. The idea that a turbo will “freewheel” is not correct – it is still pumping air and, in the absence of any exhaust gas energy (when the throttle is closed) to keep the turbine spinning, will still slow down rapidly. It must be mentioned that the same lightweight material technology used to improve turbo spool-up also means it will slow down more readily when the throttle closes.

Factory turbo cars are usually fitted with relatively small, lightweight and therefore fast-spooling turbos, and intercoolers with small volumes. These features alone play a significant role in reducing lag, and therefore an increase in lag from the DV is acceptable in order to ensure compressor surge never occurs.

So to summarise:

- Venting no air during throttle lift results in compressor surge where the turbo rapidly slows and potentially damaging pressure spikes and pulses result.

- Venting lots of air eliminates compressor surge, but increases the turbo system’s lag by evacuating all pressure from the intercooler piping.

The best throttle response and lag reduction is to be found somewhere in between the two extremes of no DV and a factory-style DV. This is the basis of GFB’s TMS principle.

TMS principle

By designing and adjusting a TMS valve to specifically suit the application, GFB has made it possible to reduce turbo lag during gearshifts or when modulating the throttle by holding some pressure in the intercooler and piping. By venting only enough air to prevent compressor surge, pressure in the intercooler can be maintained for as long as the turbo’s inertia will allow.

During a high RPM/full throttle gearshift for example, boost pressure in the intercooler with a factory valve will typically drop to zero (atmospheric) before the throttle is re-opened. With a GFB TMS however, the rate at which the boost pressure drops can be reduced, so that it is possible to have positive pressure in the intercooler when the throttle re-opens. This gives more power immediately as pressure is higher, and also reduces the time taken to reach maximum boost.

Example

To demonstrate this, our test bed was a 1.8L turbo engine, with a large front-mount intercooler running 12psi peak boost. A data logger measured the throttle position and the manifold pressure.

Since this engine had no factory valve fitted, we used one from a Mitsubishi EVO IX to begin with for a base run.

A full boost 2nd-3rd gearshift was performed at 6000RPM and the results logged.

From the data we can measure the actual lag time from when the throttle first starts to re-open, to when full boost is reached.

The factory valve was then replaced with a GFB TMS valve, and the spring was adjusted as firm as possible without incurring compressor surge and the test repeated.

Results

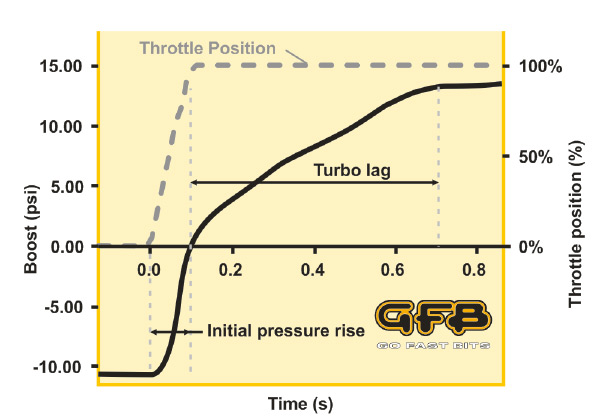

The graph opposite shows manifold pressure and throttle position, starting from part-way through a gearshift, since it’s what happens when the throttle re-opens that we’re interested in.

Importantly, the manifold pressure trace shows two distinct zones: Initial pressure rise and turbo lag.

The initial pressure rise is similar to the behaviour of a normally aspirated engine in that as the throttle opens, the manifold pressure rapidly rises from vacuum to the supply pressure (i.e. the pressure upstream of the throttle – on an NA engine this will usually be atmospheric pressure).

The pressure increase then abruptly reduces in rate as the manifold equalizes with the supply pressure, and the turbo is still spooling up. The rate of pressure increase during spool up is determined by the engine and turbo system itself, and the time taken doing so is defined as turbo lag.

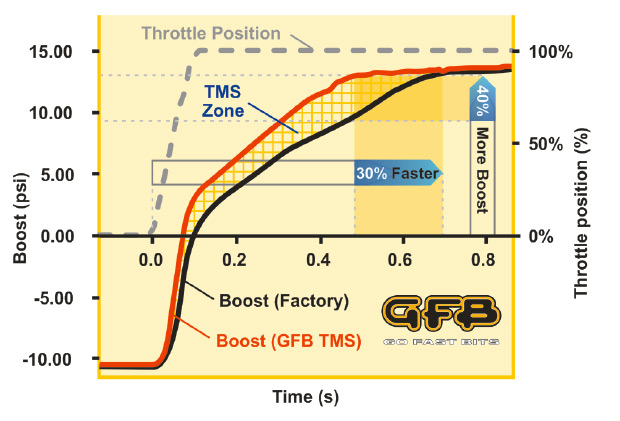

tms-solution-2This graph shows the two test runs overlaid, with the red line representing the manifold pressure with the GFB TMS fitted, and the black line is with the factory valve fitted.

It can be seen that with the GFB TMS, the initial manifold pressure rise doesn’t stop at zero (atmospheric) as it does with the factory valve, but continues to 2.5psi.

This means that the supply pressure in the intercooler when the throttle is re-opened is 2.5psi rather than zero, and as a consequence, peak boost is achieved 0.21 seconds (30%) sooner than with the factory valve.

Peak numbers aside, it can be seen on the graph that higher boost pressure (and therefore engine power) is available during the entire spool up process.

Conclusion

A GFB TMS valve can help maintain boost pressure in the intercooler and pipes whenever the throttle is closed with the following benefits:

- Higher boost available upon re-opening the throttle for instant response

- More boost throughout the spool-up process (up to 40%)

- Shorter lag time (reduced by up to 30%)

- No compressor surge

When driving, a factory diverter valve will typically create a slight hesitation immediately upon re-opening the throttle, followed by a noticeable turbo lag. Fitting a GFB TMS will sharpen the response by eliminating the hesitation and then reducing time to peak boost. During a quarter mile race (where 3-4 gearshifts can occur) the time saving is quite significant, and on the circuit the power delivery upon corner exit is sharper and more responsive to the throttle opening.

Click here to learn more about Compressor Surge.