NEW RANGE TO SUIT:

-

I30/Elantra Sedan N Line

-

I20 N

-

Sonata N Line

-

Kona N Line

With over 20 years in the business of designing and manufacturing performance products, GFB have learned a thing or two about managing boosted air, along with the difference between a good blow-off valve, and a great one!

Quality and performance are built into all GFB valves, so regardless of which one you choose, your investment will last a lifetime and offer the best possible throttle response and boost holding (read more about GFB’s Turbo Management System and performance on the next page).

Our range of blow off valves for Hyundai and Kia’s latest generation “Smartstream” engines offer many different options when it comes to venting sound, from silent to extremely loud, and anywhere in between. Because these engines do not use a MAF sensor, venting to atmosphere for sound will not cause drivability issues.

Unbeatable quality, direct bolt-on fit, exclusive venting bias adjustment to control the sound, lifetime warranty, AND a performance benefit – that’s what we mean by Performance Without Compromise.

WHAT IS GFB’S TURBO MANAGEMENT SYSTEM?

GFB’s Turbo Management System (TMS) is a method of controlling the flow rate of the air released by the blow off/diverter valve to improve throttle response.

On all modern Hyundai engines, the factory diverter valve is controlled by the ECU via a solenoid and a vacuum reservoir.

When the ECU sees the throttle starting to close, it turns the solenoid on which opens the factory diverter. Whilst this system has a fast response time, it cannot open or close the diverter valve progressively – it’s either open or shut.

This method compromises throttle response and also introduces dips and spikes in the torque delivery during traction control events, or when the throttle is being modulated – even the smallest negative throttle movement will fully open the diverter, and the torque will drop significantly. Reapplication of the throttle closes the valve and torque steps up again, making the throttle response jerky and nonlinear when driving aggressively.

GFB’s blow off valves combat these issues by introducing progressive valve moment in response to the amount of boost present when the ECU activates the solenoid. If boost pressure is low, a GFB valve only opens a small amount. When lifting off at high boost, it opens fully to reduce the initial pressure spike, then starts to close as the pressure is reduced. This helps maintain a small amount of boost pressure in the intercooler tract for a short amount of time, which smooths the torque transitions during throttle modulation, and also means that boost returns to peak faster after a brief throttle lift off since it doesn’t have to rise from zero.

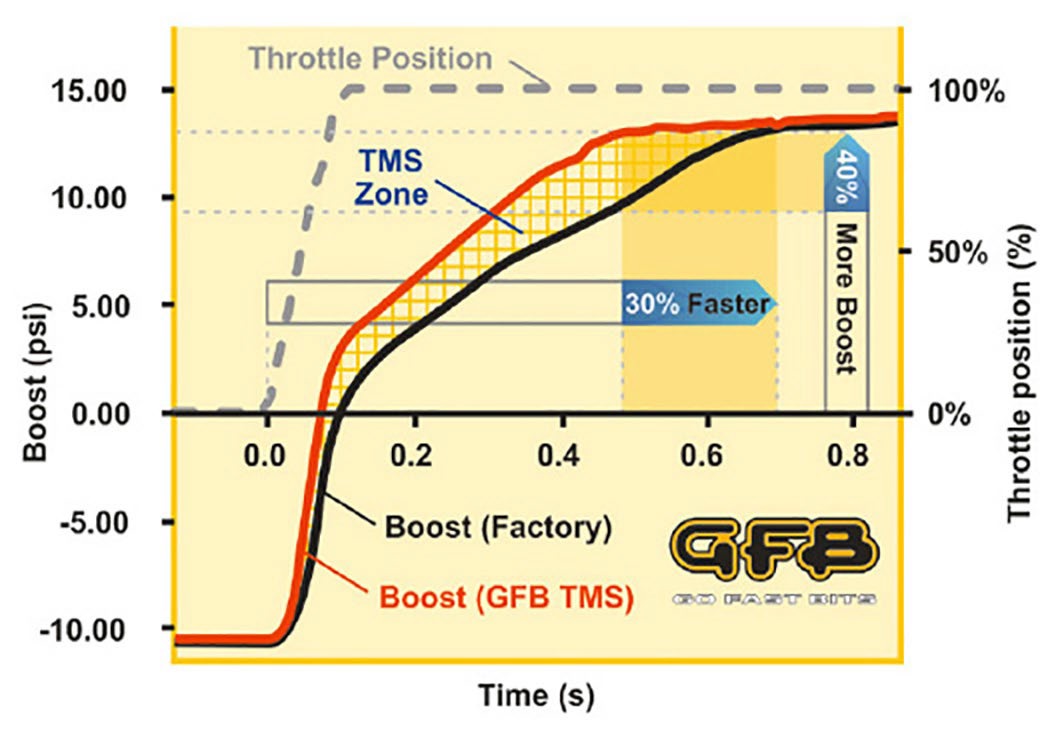

This effect can be seen in the graph below, which shows the improvement in boost pressure rise time following a brief throttle lift. You can clearly see that when the throttle is re-opened, manifold pressure with the GFB blow off valve jumps immediately to around 2.5psi before the turbos start spooling. By comparison, the factory valve results in a 30% longer time to peak boost, because it has remained completely open during the entire throttle closure and the pressure in the intercooler dropped to zero.

All GFB valves feature the TMS benefit, which ensures you get the most out of your boost pressure wherever possible.